Wednesday, October 3rd 2018

3D QLC Woes - Manufacturers Fighting to Get Yields Above 50%

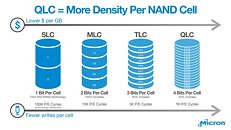

3D QLC (quad-level cell) is the latest, manufacture-ready technology to grace the NAND panorama, with promises of increased density over 3D TLC (triple-level cell), thus bringing pricing per GB even lower. However, as with all wafer-based PC components, yields are an extremely important part of that process. Cost reduction can only be attained if manufacturing allows for a given percentage of a wafer to be fully functional and without defects that compromise its feature-set or performance. However, as cell design becomes more complex in a bid to increase areal density, yields have taken longer to mature.

According to DigiTimes, 3D TLC yields have only gotten off the ground in the beginning of this year - right around the time companies were rolling out their 3D QLC designs. And if TLC took longer than expected to achieve respectable yields, it seems that QLC memory will take even longer - we already knew that the Intel-Micron venture on QLC was facing less than 50% yields, but DigiTimes has now extended this struggle to what seems to be the entire NAND manufacturing industry (Samsung Electronics, SK Hynix, Toshiba/ Western Digital and Micron Technology/Intel). The result? Expected price fluctuations in the beginning of 2019, as predicted production volume fails to meet both projected and actual demand, with 3D TLC supplies having to cope with increased market demands.

Source:

DigiTimes

According to DigiTimes, 3D TLC yields have only gotten off the ground in the beginning of this year - right around the time companies were rolling out their 3D QLC designs. And if TLC took longer than expected to achieve respectable yields, it seems that QLC memory will take even longer - we already knew that the Intel-Micron venture on QLC was facing less than 50% yields, but DigiTimes has now extended this struggle to what seems to be the entire NAND manufacturing industry (Samsung Electronics, SK Hynix, Toshiba/ Western Digital and Micron Technology/Intel). The result? Expected price fluctuations in the beginning of 2019, as predicted production volume fails to meet both projected and actual demand, with 3D TLC supplies having to cope with increased market demands.

31 Comments on 3D QLC Woes - Manufacturers Fighting to Get Yields Above 50%

I skipped TLC for SSDs and only just now got my first 3D TLC SSD. QLC just looks too iffy to me.In other words, if you need an SSD, get one now, while they're cheap-ish.

I think the main problem with QLC is performance. The Intel 660p for example, its a weird product. Its a slow as the average SATA SSD and is considered competitive because its now in M2 and has the potential for higher sequential speeds and IOPS. In other words, there are barely any changes when compared to a regular SATA SSD which is as cheap, a bit slower in IOPS but much more flexible in terms of placement and much faster at sustained write operations. And here comes the kicker... we're talking about a DRAM supported M2 SSD as well. Not exactly cost effective if you place it next to no-DRAM SATA SSDs...

The bottom line, if QLC doesn't significantly drop in price (as in, below $0.10/GB) the changes are so minimal for most people its not even worth taking the lower endurance rating for granted. There's just nothing substantial to justify the small price gap compared to a regular SATA SSD. The only justification right now is when you place it next to M2 SSDs exclusively... but who really does that? Its all storage, with a certain amount of performance. PCIe doesn't magically make things better and it does eat valuable lanes.

QLC on it's own does not increase complexity of a cell design. Fundamentally, a cell is exactly the same for SLC, MLC, TLC or QLC type NAND.

The supporting circuits to enable increased error correction due more fine grained voltage differentiation (in case of QLC there are 16 different voltage states, which means a very narrow voltage range for each cell value). do have to be beefed up for somewhat reliable operation (obviously controller support also plays a vital role here).

Makers can say all they want about TB written and spare cells, once these start to become unreliable it means data loss and an unstable device.

From sites that have done torture tests, personally, I'm not worried at all about 3D TLC NAND. I'd only worry about older planar NAND. But even then you can compensate by just getting a bigger drive.

www.newegg.com/Product/Product.aspx?Item=N82E16820167462

I've seen so many SSDs and HDDs fail, I can tell you it happens a lot.

I'm excited for QLC, not for my desktop needs, but I wouldn't mind a file server based on QLC SSDs for a WORM like usage.

Almost all of my SSDs are Intel, but I've set up machines with Samsung etc., but they are not better. Samsung 950/960 are known to have firmware issues on Linux. But I've never seen a recent Intel (520/530/535/540) having firmware issues in Linux.

For the record, my bad Intel 540s was running Ubuntu 16.04, not that I have any evidence supporting that the OS killed it. It's getting random bad sectors all over, which I assume is bad flash.Mostly, I'm talking about rapidly growing SMART error counts.

For instance, my bad 540s saw random files and folders all over become unreadable. It's still not completely dead, but not usable.

I haven't seen any SSD issues and only heavily used mechanicals have failed in general...unless we're adding in crapgates.

In essence good NAND, SLC or MLC, will outlast most human attempts to exhaust their PE cycles.The QLC yields were never disclosed, probably because there's only a handful of drives using it.