Wednesday, April 21st 2021

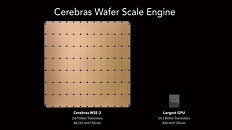

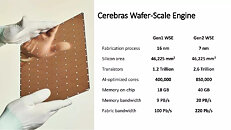

Cerebras Updates Wafer Scale Engine on 7 nm - 2.6 Trillion Transistors, 40 GB Onboard SRAM, 850,000 Cores, 12" Wafer

Cerebras has announced the successor to their record-breaking Wafer Scale Engine. The newly re-engineered Wafer Scale Engine 2 has been redesigned for TSMC's 7 nm manufacturing process - a severe improvement over the original's 16 nm. That Cerebras has moved on to TSMC's 7 nm for this giant, wafer-sized accelerator is telling of the confidence and state of yields on TSMC's 7 nm - if the process wasn't considered to be stable and guaranteeing incredibly good yields, I doubt such an effort would have been undertaken.The updated Wafer Scale Engine 2 now packs a staggering 850,000 cores (compared to the original's 400,000); offers 40 GB of on-chip SRAM (up from 18 GB); 20 PetaBytes/s memory bandwidth (up from 9 PB/s), and 220 PB/s interconnect fabric speed (up from 100 PB/s). These improvements and increases have been achieved with the same power envelope as the original, set at a staggering 20 kW (system) and 15 kW (chip) power consumption. These are enabled by the much higher transistor density of 7 nm vs 16 nm, which enables 2.6 Trillion transistors on the Wafer Scale Engine 2 compared to a "paltry" 1.2 Trillion on the original, 16 nm version of it, whilst occupying the same 46,225 square millimeters (about 21.5 x 21.5 cm). Cerebras has one-upped itself, building upon what already had to be the most impressive feat of classical chip engineering.

Source:

Tom's Hardware

25 Comments on Cerebras Updates Wafer Scale Engine on 7 nm - 2.6 Trillion Transistors, 40 GB Onboard SRAM, 850,000 Cores, 12" Wafer

Die size is after all just a detail.

Reminds me, it's time for dinner.... :D

That said, still love the idea.

i didn't found in their white papers how to clean them after

I mean, it costs like 50USD or so to print chips on single wafer, so even with 5% yield rate you would only need 20 wafers before you get the perfect one. Thats only a kilo of USD. Selling that perfect wafer for a million covers production costs for decades.