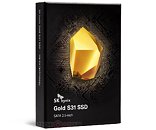

SK Hynix Announces the Gold S31 Consumer SATA SSD

SK hynix Inc. announced today the launch of its "Gold S31" solid-state drive (SSD). Gold S31 (SATA III - first generation) is the first of the Company's new SuperCore series of consumer SSDs, an internal drive lineup based on SK hynix's core technology. With its speed and reliability, SK hynix's Gold S31 will be a perfect choice for all PC users, particularly for gamers, designers, and content creators. Gold S31 pushes the limits on high-performance SSDs, providing users the next level of speed with sequential read speeds up to 560 MB/s, as well as superior quality, reliability, and five-year warranty.

The 2.5-inch drive supports the SATA III interface based on 3D NAND Flash technology, and is now available in 1 TB, 500 GB and 250 GB capacities on Amazon US. All key components in Gold S31, from NAND Flash and built-in controller to DRAM and firmware, were designed and produced by SK hynix. The in-house components are built for robust performance and reliability.

The 2.5-inch drive supports the SATA III interface based on 3D NAND Flash technology, and is now available in 1 TB, 500 GB and 250 GB capacities on Amazon US. All key components in Gold S31, from NAND Flash and built-in controller to DRAM and firmware, were designed and produced by SK hynix. The in-house components are built for robust performance and reliability.