Wednesday, December 23rd 2020

Intel Expands 10nm Manufacturing Capacity

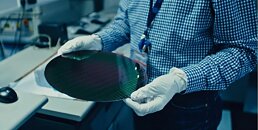

In response to incredible customer demand, Intel has doubled its combined 14 nm and 10 nm manufacturing capacity over the past few years. To do this, the company found innovative ways to deliver more output within existing capacity through yield improvement projects and significant investments in capacity expansion. This video recounts that journey, which even included re-purposing existing lab and office space for manufacturing.

"Over the last three years, we have doubled our wafer volume capacity, and that was a significant investment. Moving forward, we're not stopping… We are continuing to invest into factory capacity to ensure we can keep up with the growing needs of our customers," says Keyvan Esfarjani, senior vice president and general manager of Manufacturing and Operations at Intel. The company also ramped its new 10 nm process this year. Intel currently manufactures 10 nm products in high volumes at its Oregon and Arizona sites in the U.S. and its site in Israel.In 2020, Intel introduced an expanding lineup of 10 nm products including 11th Gen Intel Core processors and the Intel Atom P5900, a system-on-chip for wireless base stations. In addition, the company introduced 10 nm SuperFin technology, which enables the largest single intranode enhancement in Intel's history and delivers performance improvements comparable to a full-node transition.

Esfarjani explains: "10 nm progress is coming along quite well. We have three high-volume manufacturing operations that are going full steam ahead to see how we can do more, better and faster, and continue to support our customers."

NOTE: Intel's capacity expansion program has been a multiyear journey. The factory and office footage in this video was captured prior to Covid-19 safety measures. Intel workers currently working on-site observe appropriate social distancing and mask measures in accordance with internal policies and local requirements.

"Over the last three years, we have doubled our wafer volume capacity, and that was a significant investment. Moving forward, we're not stopping… We are continuing to invest into factory capacity to ensure we can keep up with the growing needs of our customers," says Keyvan Esfarjani, senior vice president and general manager of Manufacturing and Operations at Intel. The company also ramped its new 10 nm process this year. Intel currently manufactures 10 nm products in high volumes at its Oregon and Arizona sites in the U.S. and its site in Israel.In 2020, Intel introduced an expanding lineup of 10 nm products including 11th Gen Intel Core processors and the Intel Atom P5900, a system-on-chip for wireless base stations. In addition, the company introduced 10 nm SuperFin technology, which enables the largest single intranode enhancement in Intel's history and delivers performance improvements comparable to a full-node transition.

Esfarjani explains: "10 nm progress is coming along quite well. We have three high-volume manufacturing operations that are going full steam ahead to see how we can do more, better and faster, and continue to support our customers."

NOTE: Intel's capacity expansion program has been a multiyear journey. The factory and office footage in this video was captured prior to Covid-19 safety measures. Intel workers currently working on-site observe appropriate social distancing and mask measures in accordance with internal policies and local requirements.

66 Comments on Intel Expands 10nm Manufacturing Capacity

Where are the next gen processors? And no, that 14 nm abomination known as Rocket Lake doesn't qualify.

I mean otherwise yay, cheer, we can still buy Skylake v2 and you're still making it. Thanks, Intel. Oh yeah we can also buy 10nm Skylake V3 on super low clocks, too. Yay x2... What happened to those shiny roadmaps with new stuff?Not sure, seems like TSMC is doing just fine in quality and in quantity and it doesn't really seem to affect the AMD product stacks in any negative way.

In the end a chip's a chip... Again... look at GF. The reason they can't stay current is because they chose not to. They just moved to a different market, not because they wanted to, but because there is no demand for their node in their old one. I still hope both Intel and GF get a path back to the frontline again... but its clear they're not on it now. And China is also ready, willing and might soon be able to move to smaller nodes too.

Its a bit of a similar struggle as the panel OEMs have for OLED technology. LG won, and is like TSMC right now, building a superior product while everyone else is stacking boxes full of tricks on top of LCD to keep it relevant. They even got VESA to implement an HDR standard for monitors that can't display it proper in the first place with the whole HDR400 etc. spec. Even the HDR1000 ones are horrible because the black point simply is too high for comfortably viewing the new contrast steps. People want better panels, everyone can see LCD has its problems in many ways, even on a VA or IPS. Same thing goes for chips. If you stay on bigger nodes than 7nm, you're going to lose even if product is marketable.

Similarly, its more expensive now to make a top-end full array local dimming LCD, than it is to make an OLED screen of the same spec... so you can't keep that up.

:confused:

Whatever they have currently - 14nm and 10nm capacity - is at full blast. They are working on improving yields, supposedly for 10nm. They are also investing is new fabs and/or refitting existing fabs.

It's so broken that there are still ZERO server or desktop chips on 10nm and next year we'll get 2018's 'Cove' architecture on desktop... BACKPORTED to 14++++nm

Tell me again how they doubled their 10nm capacity of a completely broken fab?