Wednesday, December 8th 2021

Intel Z690 Motherboard Costs Explained

There has been a lot of discourse about the cost of Z690 motherboards, so we decided to ask around to find out what has changed compared to the previous generation of Intel motherboards. There are obviously several factors that have come together to create something like the perfect storm, as the simple answer is that all parts combined have resulted in more expensive motherboards, but there are a few key components that are major contributing factors.

A lot of speculation has been about the cost of the PCB itself and although it's correct that the PCB is a contributing factor, we're talking about a couple of dollars in extra cost, not only for the higher quality PCB materials themselves but also the fact that boards with DDR5 memory are more costly to produce, as more care needs to be taken with the overall design. However, the big surprise to us is that the single part that has driven up the cost the most is the physical LGA-17xx CPU socket and retention mechanism, which is apparently around four times as expensive as the LGA-12xx socket.Although we don't have a precise cost of either socket, an LGA-115x socket costs around US$5 in comparatively small volumes and as motherboard makers are buying far greater volumes of sockets, they are likely to pay less per unit. Even so, it seems like LGA-17xx sockets should be somewhere around US$10-15, even in large volumes. This makes the CPU socket the second most expensive component on most Z690 motherboards after the chipset, which has a list price of US$51, which is $1 more than the Z590 chipset.

Another contributing factor is the power design, as Intel moved from IMVP8 to IMVP9.1, which meant a move from DrMOS (Driver MosFet) to SPS (Smart Power Stage) modules. This design change has led to the use of not only more expensive power designs, but these parts are also in short supply, which means that each power phase is about twice the price on a Z690 motherboard compared to a Z590 motherboard. On the plus side, they should be more efficient and have lower thermals than a DrMOS type design and prices are likely to come down over time. However, as we're seeing boards with more power stages than in the past, this is as far as we can tell, the second most costly design change of the Z690 motherboards. It's also not possible to use an IMVP8 power design for a Z690 motherboard, so there's no way of saving any cost here, except using fewer power phases.

On high-end motherboards that have two PCIe 5.0 slots, a PCIe 5.0 retimer is also needed. Unfortunately we were unable to find the pricing of PCIe 5.0 retimers, but an eight lane PCIe 4.0 retimer costs around US$45 on fairly low quantities, so an estimated guess is that the motherboard makers are paying as much as US$20-30 each for them in greater quantities. However, this isn't a concern for most Z690 motherboards, as it's not required for a single PCIe 5.0 slot.

As far as the physical PCIe 5.0 SMT slots are concerned, the cost difference is 10 to 20 percent, which means a few cents per connector, in the kind of quantities that the motherboard makers purchase. A requirement here is that the board makers need to have the right kind of SMD/SMT and pick and place machines to be able to mount the PCIe 5.0 SMT slots, since older through hole slots were added by hand at the motherboard factories. As such, it's likely that some of the cost of investing in new machines are likely to spill over to the cost of each motherboard, until the machines are paid off.

None of the above takes into consideration the current situation in the world, where there's a shortage or a price hike of just about every conceivable part that goes into making a motherboard. This includes everything from the cost of aluminium to resistors and capacitors. One thing of note here is that most motherboard makers used to place their component orders three to four months ahead of production, something that is no longer possible when many, if not most components have a 52 week lead time. As such, they have had to make big changes to how they place orders and this too is likely to lead to further increases in costs. We're also hearing whispers of potential price increases coming early next year for some parts, so if you haven't gotten the motherboard you were looking to buy yet, now might be as good a time as ever to do so.

A lot of speculation has been about the cost of the PCB itself and although it's correct that the PCB is a contributing factor, we're talking about a couple of dollars in extra cost, not only for the higher quality PCB materials themselves but also the fact that boards with DDR5 memory are more costly to produce, as more care needs to be taken with the overall design. However, the big surprise to us is that the single part that has driven up the cost the most is the physical LGA-17xx CPU socket and retention mechanism, which is apparently around four times as expensive as the LGA-12xx socket.Although we don't have a precise cost of either socket, an LGA-115x socket costs around US$5 in comparatively small volumes and as motherboard makers are buying far greater volumes of sockets, they are likely to pay less per unit. Even so, it seems like LGA-17xx sockets should be somewhere around US$10-15, even in large volumes. This makes the CPU socket the second most expensive component on most Z690 motherboards after the chipset, which has a list price of US$51, which is $1 more than the Z590 chipset.

Another contributing factor is the power design, as Intel moved from IMVP8 to IMVP9.1, which meant a move from DrMOS (Driver MosFet) to SPS (Smart Power Stage) modules. This design change has led to the use of not only more expensive power designs, but these parts are also in short supply, which means that each power phase is about twice the price on a Z690 motherboard compared to a Z590 motherboard. On the plus side, they should be more efficient and have lower thermals than a DrMOS type design and prices are likely to come down over time. However, as we're seeing boards with more power stages than in the past, this is as far as we can tell, the second most costly design change of the Z690 motherboards. It's also not possible to use an IMVP8 power design for a Z690 motherboard, so there's no way of saving any cost here, except using fewer power phases.

On high-end motherboards that have two PCIe 5.0 slots, a PCIe 5.0 retimer is also needed. Unfortunately we were unable to find the pricing of PCIe 5.0 retimers, but an eight lane PCIe 4.0 retimer costs around US$45 on fairly low quantities, so an estimated guess is that the motherboard makers are paying as much as US$20-30 each for them in greater quantities. However, this isn't a concern for most Z690 motherboards, as it's not required for a single PCIe 5.0 slot.

As far as the physical PCIe 5.0 SMT slots are concerned, the cost difference is 10 to 20 percent, which means a few cents per connector, in the kind of quantities that the motherboard makers purchase. A requirement here is that the board makers need to have the right kind of SMD/SMT and pick and place machines to be able to mount the PCIe 5.0 SMT slots, since older through hole slots were added by hand at the motherboard factories. As such, it's likely that some of the cost of investing in new machines are likely to spill over to the cost of each motherboard, until the machines are paid off.

None of the above takes into consideration the current situation in the world, where there's a shortage or a price hike of just about every conceivable part that goes into making a motherboard. This includes everything from the cost of aluminium to resistors and capacitors. One thing of note here is that most motherboard makers used to place their component orders three to four months ahead of production, something that is no longer possible when many, if not most components have a 52 week lead time. As such, they have had to make big changes to how they place orders and this too is likely to lead to further increases in costs. We're also hearing whispers of potential price increases coming early next year for some parts, so if you haven't gotten the motherboard you were looking to buy yet, now might be as good a time as ever to do so.

41 Comments on Intel Z690 Motherboard Costs Explained

I firmly believe that mfgr's are just jackin us for these mobo's just because:

A) They are the latest/greatest thing available

B) They are using the pandemic, chip shortages, and other supply chain issues to justify their greedy, shameful actions.

C) They know there are dumbasses out there that will pay top dollar just for the epeen of having #1 above, regardless of whether they need it or have to go into debt to get it...

Seems like yet anutha case of extreme Capitalism101 gone really, really bad :D

What size is a low vs high quantity order tho? Could it be a couple hundred vs several thousands? I'm sure the size of the order and the promise of follow up orders could mean each order is negotiated to coincide with the current market. Who says prices are set in stone? I'd bet that, up until yesterday, the quality capacitor that cost $0.05(ea.) on orders per thousand, and today cost $0.08 because of the market issues.

Regardless, board manufacturers are inflating prices way too much, taking advantage of the current market. Thats capitalism for ya..,..:D

Around 1k tend to be considered a small order, 10-100k a large order, but it obviously depends on the part. Something like resistors or capacitors would be in the millions.

Obviously anything can be negotiated, but the Taiwanese board makers aren't Samsung or even Sony or LG when it comes to order quantities, if we're going to compare to some consumer electronics brands.

Asus might come close, but Gigabyte, MSI and ASRock simply don't have the kind of buying power needed to get really good pricing.

Actually, you'd be surprised. Most have around 10 percent margin, with only one brand having double that or a bit more. I'll let you guess who that is. This does of course vary between SKUs as well.

Keep in mind that the board makers don't control the retail pricing, although they do have an MSRP, but it doesn't mean the retailers have to follow that, as we've seen with graphics cards.

So what we see in retail doesn't reflect the profit margins of the board makers.

One final point that I didn't make, is that all the board makers are getting MDF (Marketing Development Funds) from Intel, to help them promote Intel based product. Often a large part of their profit comes from MDF rather than pure sales.I didn't get a proper answer to that question, except ask Lotes, Foxconn etc.

A guess would be that it has something to do with the DDR5 and PCIe 5.0 signal tolerances, but I could be wrong here.

Like WHAT THE FU#K!!

www.usb.org/

I presume you look forward to USB4 Gen 3×2?

en.wikipedia.org/wiki/USB4#USB_3.x_%E2%80%93_4.x_data_transfer_modesThat's USB PD, a whole nother can of worms. Ideally what you want, for future proofing, is a USB Power Delivery Rev. 3.1 (V. 1.2) compliant cable.

Keep in mind that most high Amperage cables are limited to USB 2.0 speeds...

en.wikipedia.org/wiki/USB#PD

Shipping is a small part of the overall cost increase for motherboards.

If we take Asus as example, they have five SKUs with two PCIe 5.0 slots, with the cheapest one being US$465 or there abouts, with the next model up being $600.

As such, we're talking low volume motherboards, so maybe 10-20k chips per board maker per month, most likely less, as the other board makers have fewer SKUs with two PCIe 5.0 slots.

So I very much doubt they're getting really good pricing on these parts, especially as there are limited companies that make them so far.

However, they can also be used for CXL, so if said companies use them for their server boards as well, it might be an extra 5k per month, but nothing like the numbers you're thinking about.

I can't see why 500 pins had to be added (with an option to add 100 more for Next Lake), and LGA1700 and LGA1200 pinouts don't seem to be public. The width of the widest interfaces (PCIe, DMI, DDR) hasn't changed much, at least if same pins are used for DDR4 and DDR5. However, it's possible that Next Lake, a multi-die design, will require a much more complex power delivery.

Personally i think it's a good thing that Intel atleast tried to be a little more forward looking when designing the socket instead of requiring motherboard upgrade every two generations or with some boards being EOL within 6 months (looking at Z590).

At one of our etailers i can only see 5-8 boards that actually list the audio chipset, 2x 4080, 2x ROG Supreme FX(that could be anything because it's Asus's people tweaking it a little and then calling it anything they want but i'm guessing it's either ALC4080 or ALC4082 aswell))and 1x or 2x 4082; everything else is listed as 5.1 audio or 7.1 audio.

I had ALC897 on my Asus Z97 PRO Gamer i bought in 2015 with my 4690K and that was a midrange mobo priced at 150$.

On second thought you're right, it is immensely hilarious.

Edit: I forgot to mention the origin of 115x - 1156

Also, @TheLostSwede , are the companies we talk about most often really the largest desktop motherboard manufacturers these days by volume? Lesser known companies that make stuff for HP/Dell/Lenovo, like ECS and Foxconn, may be at/near the top of the list. (And they sure are interested in procuring cheap sockets for their H610 boards.)

ummm why?? That just doesn't make sense.

I am far away from being a conspiracy fanatic, but a lot of these price hikes seem to lean more towards collusion/gouging/greed, than labour, materials and other incremental costs/expenses.

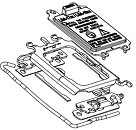

I suspect it's due to the complexity of all those delicate pins and more of them per socket. The wiring traces on the board along different PCB layers seems like it would be a cake walk by comparison where as the socket pins look a bit like this. Behold people Intel's new LGA socket design.