Tuesday, April 27th 2021

ATP Launches PCIe Gen3 x4 NVMe SSDs in M.2 Type 1620 HSBGA Package

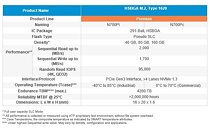

ATP Electronics, the global leader in specialized storage and memory solutions, has announced the launch of its tiniest NVMe flash storage offering: the N700 Series PCIe Gen3 x4 NVMe solid state drives (SSDs, which are available as M.2 Type 1620 heatsink ball-grid array (HSBGA) package. Complying with M.2 specifications, the M.2 Type 1620 HSBGA measures just 16 (L) x 20 (W) x 1.6 (H) mm, supporting high-speed PCIe 3.0 interface x4 lanes and NVMe protocol to deliver up to 32 Gb/s bandwidth at 8 Gb/s per lane. The soldered-down design makes them vibration-proof, while the 291-ball packaging takes up minimal space within tightly confined systems.

For customers who prefer a removable and field-replaceable design, ATP can accommodate the HSBGA onto an M.2 2230 module with the same firmware and NAND configuration. Both variants are suitable for thin and light systems in embedded, industrial and mobile applications. N700 Series SSDs are built with 3D triple-level cell (TLC) configured as pseudo single-level cell (pSLC) NAND flash. By storing only one bit per cell, they increase the reliability and endurance of the NAND flash memory, while benefiting from the lower cost compared with native SLC, due to the higher cell density.These SSDs are outfitted with a heatsink on top, which complements system airflow to enhance heat dissipation and keep the BGA SSD cool while offering 2X-3X better sustainable performance.

The optimized power consumption of just 5 mW during Power State 4 (Sleep Mode) translates to big power savings.

BGA SSD technology allows the NAND flash and controller to be integrated into one package that is lightweight yet offers powerhouse performance and ample capacities. N700 Series SSDs come in 40/80/160 GB and are packed with advanced features to meet the ultra-portability and reliability requirements of ultra-compact Internet of Things (IoT) devices and embedded systems. They provide high-speed reliable storage in harsh environments such as in transportation, aerospace, smart factories, mining operations, steel fabrication and more.

N700 Series SSDs are available in both C-Temp (0°C to 70°C) and I-Temp (-40°C to 85°C) ratings. They all undergo rigorous tests, such as Rapid Diagnostic Testing (RDT), to screen out weak blocks and ensure reliability and robustness even in extreme operating conditions.

N700 Series Key Features

For customers who prefer a removable and field-replaceable design, ATP can accommodate the HSBGA onto an M.2 2230 module with the same firmware and NAND configuration. Both variants are suitable for thin and light systems in embedded, industrial and mobile applications. N700 Series SSDs are built with 3D triple-level cell (TLC) configured as pseudo single-level cell (pSLC) NAND flash. By storing only one bit per cell, they increase the reliability and endurance of the NAND flash memory, while benefiting from the lower cost compared with native SLC, due to the higher cell density.These SSDs are outfitted with a heatsink on top, which complements system airflow to enhance heat dissipation and keep the BGA SSD cool while offering 2X-3X better sustainable performance.

The optimized power consumption of just 5 mW during Power State 4 (Sleep Mode) translates to big power savings.

BGA SSD technology allows the NAND flash and controller to be integrated into one package that is lightweight yet offers powerhouse performance and ample capacities. N700 Series SSDs come in 40/80/160 GB and are packed with advanced features to meet the ultra-portability and reliability requirements of ultra-compact Internet of Things (IoT) devices and embedded systems. They provide high-speed reliable storage in harsh environments such as in transportation, aerospace, smart factories, mining operations, steel fabrication and more.

N700 Series SSDs are available in both C-Temp (0°C to 70°C) and I-Temp (-40°C to 85°C) ratings. They all undergo rigorous tests, such as Rapid Diagnostic Testing (RDT), to screen out weak blocks and ensure reliability and robustness even in extreme operating conditions.

N700 Series Key Features

- pSLC Mode. Configured to store only one bit per cell to increase endurance and reliability, offering 2X-3X sustainable performance.

- Stable Performance. The ATP Optimized Thermal Throttling firmware (FW) will maintain the "Steady State" condition to avoid huge performance drops that will adversely impact the system, thus optimizing best performance for application requests and enhancing overall sustained performance.

- Optimized Power Consumption. Consuming low power at only 5 mW under Power State 4 (Sleep Mode), the ATP NVMe HSBGA SSDs deliver huge power savings.

- DRAM-Less Configuration. Host Memory Buffer (HMB) support helps these DRAM-less SSDs to improve performance by obtaining DRAM resources as cache, thus overcoming the limited memory capacity within the storage and optimizing I/O performance without requiring the SSD to bring up its own DRAM

- Vibration-Resistant Storage. ATP N700 Series SSDs in M.2 Type 1620 are soldered down, making them vibration-resistant and able to withstand rigorous shaking.

- Better Thermal Dissipation. The heatsink effectively transfers heat to cool the device and keep the performance at optimal levels.

- Optional Security Features

- HW Write Protect

- HW Quick Erase

- HW Secure Erase

- SW Data Sanitization (AFSSI-5020)

- AES-256 Encryption

- TCG Opal 2.0

12 Comments on ATP Launches PCIe Gen3 x4 NVMe SSDs in M.2 Type 1620 HSBGA Package

Toshiba launched a similar SSD back in 2017.

www.businesswire.com/news/home/20170802006627/en/Toshiba-Memory-Corporation-Unveils-Single-Package-NVMeTM-Client-SSD-Utilizing-64-Layer-3D-Flash-Memory

And Samsung in 2016.

www.anandtech.com/show/10166/samsung-demos-its-first-bga-ssd

Your example doesn't really apply: the people choosing parts for a notebook are engineers. They really should know the relevant standards. It really shouldn't be a problem for them if soldered parts had a different name than slot-mounted ones. Quite the opposite, I'd say, it would make their jobs easier. The different mounting requires different trace layouts and different engineering solutions anyhow, so why use the same name? What you're asking for is a standard, which is quite different from it needing to be the same standard as something else after all.

Fixing this would be as simple as giving the different form factors different names. m.3 was already tried by Samsung (kinda shadily through adopting a name that similar to m.2 without consulting with the relevant standards body, but still), and there are a bunch of others as well. The point of the name is to signal similarity and interoperability, no? Why not call the soldered ones s.2? Or b.2, for BGA? I mean, the only limit is the imagination. Instead, they've chosen to dilute the standard through making it encompass a broad range of incompatible devices. Which really ruins the point of having a standard in the first place.

So having a strict standard for these things, beyond just size, is key to being able to offer different SKUs of a product, or to being able to order an alternative solution when your main provider lets you down.

One of the reasons everything is m.2 is because it's all PCIe plus some other interfaces specified by the m.2 standard, not just PCIe.

I did mention that they could've called it something else, but again, this is not a standard made for consumers as you seem to think, but rather for companies that build systems and devices.

Maybe you should join Intel or one of the other big companies that develop and name these standards? That would make the world a better place for everyone else, as you'd be able to influence the naming of so many things.

Regardless of whether it's a consumer or component manufacturer oriented standard, regardless of wether it's PCIe alone or PCIe+other options (miniPCIe also had provisions for USB and SATA, so I don't quite see the issue there), separate names for separate and fundamentally incompatible classes of devices makes sense. Plain and simple. You're drawing up a straw man here presenting it as if the alternative is no standard at all, rather than properly named standards. I have never at any point argued for the former, and presenting that as the main option beyond "let's call everything m.2" is, yet again, making a bad-faith argument. Please stop. It doesn't matter whether that was the situation previously - that is in no way an argument against the value of criticizing an overbroad standard. Yes, an overbroad standard is better than no standard at all, but several more specific standards would again be better than an overbroad one. I mean, in this case the issue would be solved by a simple naming structure change, as the more specific standards already exist! They've just chosen a weird common naming scheme that supposedly denominates a set of AIC form factors (with potentially different signalling standards), yet at the same also includes fundamentally different form factors. A line ought to have been drawn somewhere here, as there are too many layers of incompatibilities involved.

Mini PCIe never had solder down modules or BGA options though, did it?

I never said that, please read my first reply again, where almost the first thing I said was that they could've called it something else.

My personal opinion is that a standard with a bad name is still better than no standard at all.

Look at TransFlash, which is still widely used by various unlicensed Chinese companies in lieu of microSD which was the name the standard got in the end.

Even m.2 was originally known as Next Generation Form Factor (NGFF), but I guess that wouldn't have made sense for solder down things either.

As for makingthat's another way of sayinng you're individualizing responsibility for a systemic problem while minimizing the value of raising a complaint outside of the system. Intentionally or not, that's a bad-faith arguing tactic that does nothing beyond trying to make your opponent look either irrational or as not trying hard enough. Effectively saying "if you care so much, why don't you..." is not a rational, on-topic argument in any discussion. The same really goes for asking "what will change" - I mean, it's pretty obvious: likely nothing. But potentially, a discussion is started, and it might be brought to the attention of someone involved. It's not likely, but that's not an argument against bringing up problems. You, on the other hand, are using bad-faith arguing tactics to shut down even the potential of debate, which ... why? What's the point? What's the potential harm in discussing this?